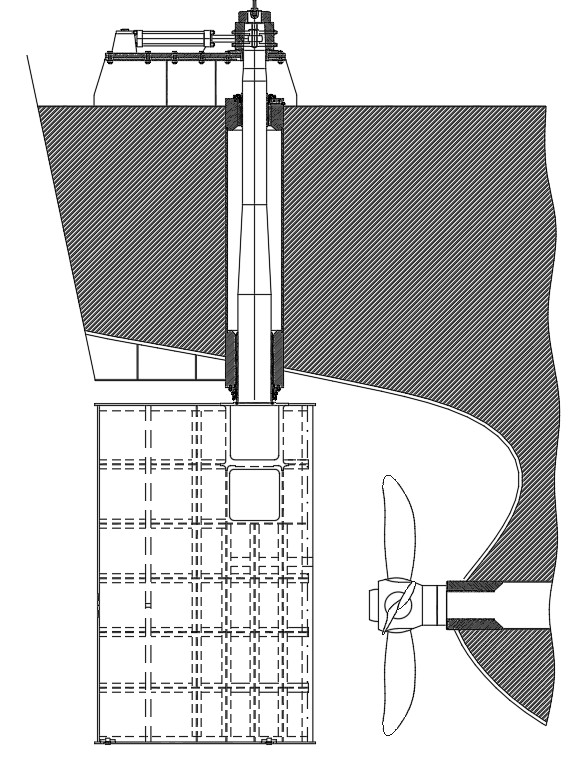

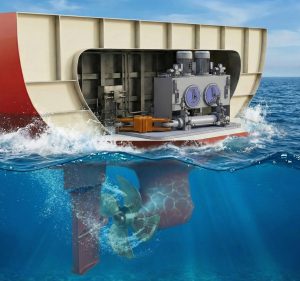

Steering Gear is a critical marine propulsion control system responsible for converting helm commands into precise rudder movements, ensuring safe and accurate maneuvering of a vessel. It is an essential component on commercial ships, offshore vessels, tugboats, ferries, workboats, and special-purpose vessels, operating reliably under all sea and weather conditions.

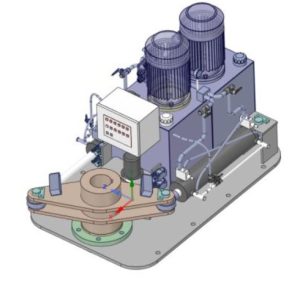

Steering gear systems are typically designed as electro-hydraulic units and can be configured as ram type or rotary vane type, depending on vessel size, rudder design, and maneuvering requirements. The system consists of hydraulic power units (HPU), actuators, control valves, oil reservoirs, piping, and control panels, all engineered for continuous-duty operation and high redundancy.

Modern steering gears are equipped with dual power units and independent control circuits to ensure fail-safe operation in compliance with international maritime safety regulations. Integrated control interfaces allow operation from the bridge, emergency steering stations, and autopilot systems, providing smooth and responsive rudder control with high positioning accuracy.

Designed for harsh marine environments, steering gear systems are manufactured from high-strength materials and protected against corrosion, vibration, and temperature variations. Advanced safety features such as overload protection, rudder angle indicators, alarms, and emergency manual operation ensure operational reliability at all times.

Steering gears are designed and manufactured in accordance with SOLAS requirements and classification society rules including DNV, ABS, LR, BV, and CE directives, ensuring compliance with the highest international safety and performance standards.

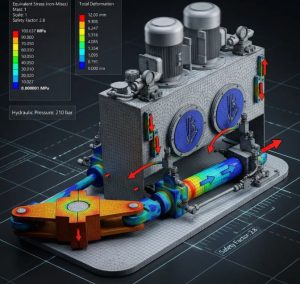

Engineering Behind a Reliable Steering Gear

A high-performance steering gear system requires:

🔹 Accurate torque calculations 🔹 Proper cylinder sizing 🔹 Structural strength verification 🔹 Fatigue and load cycle analysis 🔹 Redundant hydraulic power units 🔹 Emergency manual override systems

Engineering validation through load and stress analysis is not optional — it is essential.

Because in rough sea conditions, steering loads increase dramatically, and design margins make the difference between safe return and catastrophic failure.