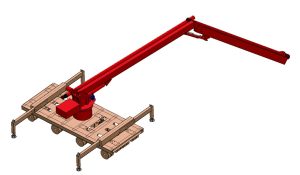

SPMT Ship Unloader

Gantry Ship Unloader

Ship Unloader Crane

High-Efficiency Bulk Material Unloading Solutions

A Ship Unloader Crane is a specialized port crane designed for the safe, fast, and efficient unloading of bulk materials from vessels to shore-based handling systems. It plays a critical role in reducing vessel turnaround time and improving terminal productivity.

Ship unloader cranes are widely used in ports, shipyards, cement terminals, power plants, and industrial bulk handling facilities.

Typical Materials Handled

-

Cement

-

Coal

-

Grain & cereals

-

Fertilizer

-

Clinker

-

Iron ore

-

Aggregate & minerals

Working Principle

The ship unloader crane operates by lifting bulk material from the ship’s cargo hold using a grab bucket or integrated unloading device. The material is then transferred to:

-

Hoppers

-

Conveyor belts

-

Screw conveyors

-

Pneumatic conveying systems

The crane ensures controlled material flow, minimizing spillage, dust emission, and cargo loss.

Types of Ship Unloader Cranes

🔹 Grab Type Ship Unloader

-

Electro-hydraulic or rope grab

-

Suitable for various bulk materials

-

Flexible and cost-effective

🔹 Continuous Ship Unloader

-

Bucket chain or screw type

-

High unloading capacity

-

Ideal for dedicated bulk terminals

🔹 Mobile Ship Unloader Crane

-

Rubber-tyred or rail-mounted

-

Fast installation and relocation

-

Suitable for multi-purpose ports

Key Technical Features

-

Lifting Capacity: Customized according to material density and grab volume

-

Outreach & Backreach: Designed to cover full vessel beam and hatch area

-

Hoisting Speed: Optimized for high cycle efficiency

-

Slewing & Luffing System: Smooth and precise motion control

-

Structural Design: FEM / ISO compliant welded steel construction

-

Drive System: Electric or hydraulic drives with frequency control

-

Control System: PLC-based automation with operator cabin or remote control

Safety & Environmental Protection

-

Overload protection systems

-

Emergency stop and fail-safe brakes

-

Anti-collision and limit switches

-

Dust suppression & enclosed transfer points

-

Low noise and vibration design

Advantages

✔ High unloading efficiency

✔ Reduced vessel waiting time

✔ Lower operating costs

✔ Environmentally friendly operation

✔ Reliable performance under harsh marine conditions

Typical Applications

-

Port and terminal ship unloading operations

-

Cement import/export terminals

-

Power plant coal unloading

-

Bulk material logistics centers

-

Shipyard and offshore support facilities

Custom Engineering & Compliance

Ship unloader cranes can be fully customized according to:

-

Vessel size and cargo type

-

Required unloading capacity (t/h)

-

Terminal layout

-

Environmental conditions

Design and manufacturing can be performed in compliance with:

-

FEM

-

ISO

-

EN

-

Class Society Requirements (ABS, BV, DNV, LR)

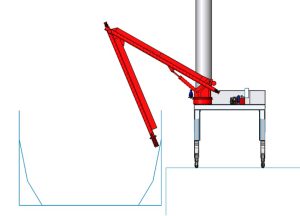

Screw Type Ship Unloader Crane

Enclosed & Dust-Free Bulk Material Unloading Solution

A Screw Type Ship Unloader Crane is a continuous bulk material unloading system designed for the efficient, enclosed, and environmentally friendly unloading of fine and dusty materials from vessels. Unlike grab-type unloaders, screw-type systems provide steady material flow, minimal spillage, and low dust emissions.

This system is especially suitable for cement terminals, grain ports, fertilizer handling facilities, and industrial bulk logistics operations.

Materials Typically Handled

-

Cement

-

Fly ash

-

Grain & cereals

-

Fertilizer

-

Powdered minerals

-

Fine bulk materials

Working Principle

The screw type ship unloader crane operates using a rotating screw conveyor (helical auger) that penetrates the ship’s cargo hold:

-

The screw rotates and continuously collects material from the hold

-

Material is conveyed through the enclosed screw casing

-

Material is transferred to:

-

Horizontal / inclined screw conveyors

-

Belt conveyors

-

Pneumatic conveying systems

-

-

The unloading process is continuous, controlled, and dust-free

The crane structure allows luffing, slewing, and hoisting movements, ensuring full access to all cargo holds.

Key Advantages Over Grab Type Unloaders

✔ Continuous unloading (no cycle time losses)

✔ Enclosed system – minimal dust emission

✔ High efficiency for fine materials

✔ Reduced cargo loss and spillage

✔ Lower environmental impact

✔ Smooth and stable operation

Main System Components

-

Vertical / Inclined Screw Conveyor

-

Horizontal Transfer Screw or Conveyor Interface

-

Crane Structure (Portal, Rail-mounted, or Mobile)

-

Electric Drive Motors with Gearboxes

-

PLC-Based Control System

-

Operator Cabin or Remote Control Station

-

Dust Filter & Ventilation Connections

Technical Features

-

Unloading Capacity: Typically 100 – 1,000 t/h (customizable)

-

Screw Diameter: Designed according to material bulk density

-

Drive System: Electric motors with frequency inverters (VFD)

-

Structure Design: FEM / ISO / EN compliant steel construction

-

Operating Mode: Continuous operation

-

Power Supply: Shore-based electric supply

-

Control: Fully automated or semi-automatic operation